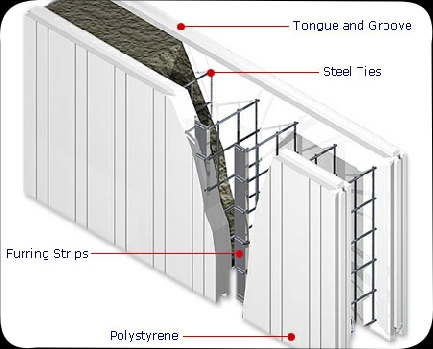

The forms are interlocking modular units that are dry-

Manufacturers commonly cite the following advantages compared to traditional building materials, especially in residential and light commercial construction. It needs to be said, however, that it is questionable what is meant by "traditional building materials"; this comparison apparently assumes different worst-

· Minimal, if any, air leaks, which improves comfort and less heat loss compared with walls without an air barrier.

· Thermal resistance (R-

· High sound absorption, which helps produce peace and quiet compared with framed walls.

· Structural integrity for better resistance to forces of nature, compared with framed walls

o Higher resale value due to longevity of materials

o More insect resistant than wood frame construction

o When the building is constructed on a concrete slab, the walls and floors form one continuous surface; this keeps out insects.

· Reduces HVAC operating costs by up to 40%.

· Construction methods are easy to learn, and manufacturers often have training available

ABOVE: ICF wall system being filled with concrete from a pump truck boom.

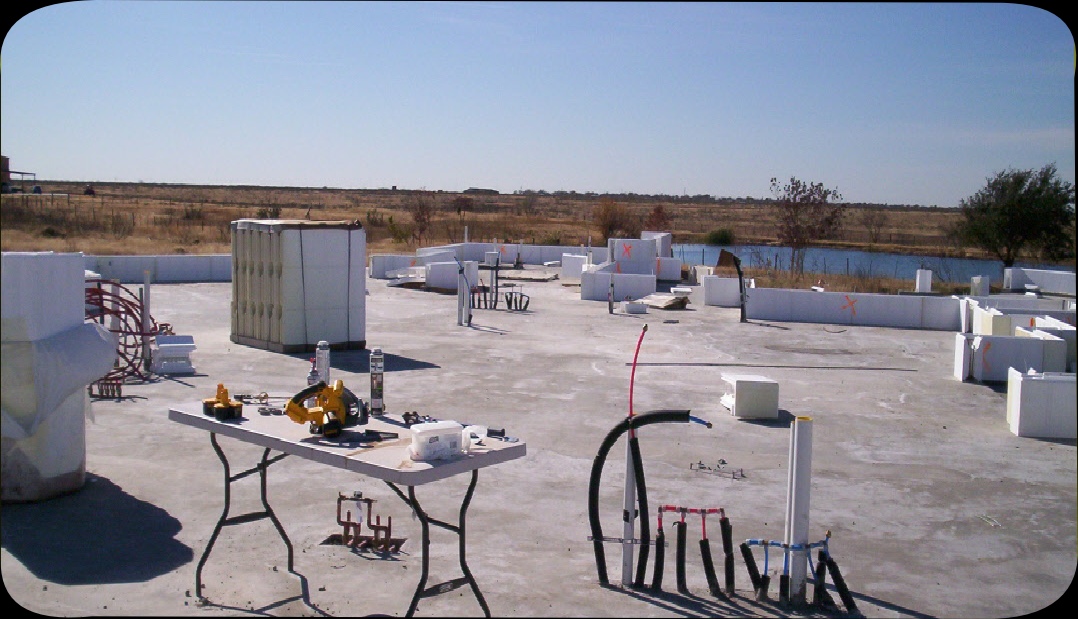

ABOVE: Erection of exterior ICF wall system using commercial braces.

ABOVE: Bracing of exterior wall assembly.

ABOVE: ICF exterior walls being constructed for the Jones house-

ABOVE: A typical door/ wall assembly using V-

ABOVE: Insulated Concrete Form (ICF) block section drawing showing how the system works.