What is R Value?

This is a very common question. Simply put-

R-

Engineers determine a R-

R-

R-

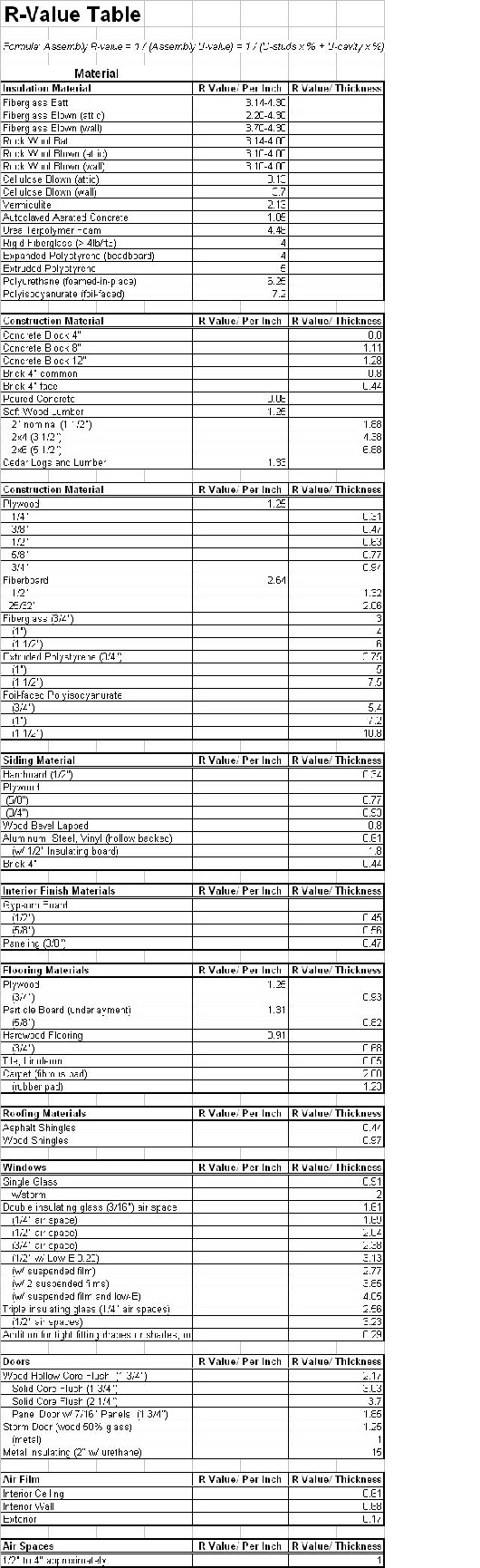

Increasing the thickness of an insulating layer increases the R value. For example, each inch of glass wool batting thickness adds approximately 3.5 (ft²·°F·h/Btu) to its R value. Heat transfer through an insulating layer is analogous to adding resistance to a series circuit with a fixed voltage. However, this only hold approximately because the effective thermal conductivity of some insulating materials depends on thickness. The addition of materials to enclose the insulation such as sheetrock and siding provides additional but typically much smaller R value.

There are many factors that come into play when using R values to compute heat loss for a particular wall. Manufacturer R values apply only to properly installed insulation. Packing two layers of R-

The R value is a measure of insulation's heat loss retardation under specified test conditions. The primary mode of heat transfer impeded by insulation is convection but unavoidably it also retards heat loss by all three heat transfer modes: conduction, convection, and radiation. The primary means of heat loss across an un insulated space is by natural convection, which occurs because of changes in air density with temperature. Insulation greatly retards natural convection. Most insulations trap air so that significant convective heat loss is eliminated leaving only conduction and radiation transfer. The primarily role of such insulation is to make the thermal conductivity of the insulation that of trapped, stagnant air. However this cannot be realized fully because the glass wool or foam is needed to prevent convection and increases the heat conduction compared to still air. Radiation heat transfer is minimized by having many surfaces interrupting a "clear view" between the inner and outer surfaces of the insulation. Such multiple surfaces are abundant in batting and porous foam. Radiation is also minimized by low emissivity (highly reflective) surfaces. Lower thermal conductivity and, therefore, high R values can be achieved by replacing air with argon when practical such as between sealed double-

R-

Increasing the thickness of an insulating layer increases the R value. For example, each inch of glass wool batting thickness adds approximately 3.5 (ft²·°F·h/Btu) to its R value. Heat transfer through an insulating layer is analogous to adding resistance to a series circuit with a fixed voltage. However, this only hold approximately because the effective thermal conductivity of some insulating materials depends on thickness. The addition of materials to enclose the insulation such as sheetrock and siding provides additional but typically much smaller R value.

There are many factors that come into play when using R values to compute heat loss for a particular wall. Manufacturer R values apply only to properly installed insulation. Packing two layers of R-

The R value is a measure of insulation's heat loss retardation under specified test conditions. The primary mode of heat transfer impeded by insulation is convection but unavoidably it also retards heat loss by all three heat transfer modes: conduction, convection, and radiation. The primary means of heat loss across an un insulated space is by natural convection, which occurs because of changes in air density with temperature. Insulation greatly retards natural convection. Most insulations trap air so that significant convective heat loss is eliminated leaving only conduction and radiation transfer. The primarily role of such insulation is to make the thermal conductivity of the insulation that of trapped, stagnant air. However this cannot be realized fully because the glass wool or foam is needed to prevent convection and increases the heat conduction compared to still air. Radiation heat transfer is minimized by having many surfaces interrupting a "clear view" between the inner and outer surfaces of the insulation. Such multiple surfaces are abundant in batting and porous foam. Radiation is also minimized by low emissivity (highly reflective) surfaces. Lower thermal conductivity and, therefore, high R values can be achieved by replacing air with argon when practical such as between sealed double-

U-

The U-

U is the inverse of R with SI units of W/(m²K).

Thickness

R-

Thermal conductivity versus apparent thermal conductivity

Thermal conductivity is conventionally defined as the rate of thermal conduction that occurs through a material. That is, for a layer of

material of known area and thickness, the rate of thermal energy transferred can be calculated based on the surface temperature differential between sides. It is not specifically related to the difference in air temperature or heating energy.

Experimentally, thermal conduction is measured by placing the material in contact between two conducting plates and measuring the energy fluxes required to maintain a certain temperature gradient.

A definition of R-

Debate remains among representatives from different segments of the U.S. insulation industry during revision of the U.S. FTC's regulations about advertising R-

Surface temperature in relationship to mode of heat transfer

There are weaknesses to using a single laboratory model to simultaneously assess the properties of a material to resist conducted, radiated or convective heating. Surface temperature varies depending on the mode of heat transfer.

In the absence of radiation or convection, the surface temperature of the insulator should equal the air temperature on each sides.

In response to thermal radiation, surface temperature depends on the thermal emissivity of the material. Light, reflective or metallic surfaces exposed to radiation tend to maintain lower temperatures than dark, non-

Convection will alter the rate of heat transfer (and surface temperature) of an insulator depending on the flow characteristics of the gas or fluid in contact with it.

With multiple modes of heat transfer, the final surface temperature (and hence observed energy flux and calculated R-

This is an important consideration in building construction because heat energy arrives in different forms and proportions. The contribution of radioactive and conductive heat sources also varies throughout the year and both are important contributors to thermal comfort.

In the hot season, solar radiation predominates as the source of heat gain. On the other hand, conductive and convective heat losses play a more significant role during the cooler months.

The limitations of R-values in evaluating radiant barriers

Further information: Radiant barrier

Further information: Cool roofs

Unlike bulk insulators, radiant barriers resist conducted heat poorly. Materials such as reflective foil have a high thermal conductivity and would function poorly as a conductive insulator. Radiant barriers retard heat flow by two means -

The question of how to quantify performance of other systems such as radiant barriers has resulted in controversy and confusion in the building industry with the use of R-

Calculating the performance of radiant barriers is more complex. The tests and procedures to evaluate bulk insulators are not applicable to radiant barriers. Although radiant barriers have high reflectivity (and low emissivity) over a range of electromagnetic spectra (including visible and UV light), its thermal advantages are mainly related to its emissivity in the infra-