Rammed earth, also known as pisé de terre or simply pisé, is a type of construction material. It is an age-

Using it involves a process of compressing a damp mixture of earth that has suitable proportions of sand, gravel and clay (sometimes with an added stabilizer) into an externally supported frame that molds the shape of a wall section creating a solid wall of earth. Traditional stabilizers such as lime or animal blood were used to stabilize the material, but cement has been the stabilizer of choice for modern times. However the use of cement is contentious as its manufacture creates 10% of man made carbon emissions. After compressing the earth the wall frames can be immediately removed and require an extent of warm dry days after construction to dry and harden. The structure can take up to two years to completely cure, and the more it cures the stronger the structure becomes. When the process is complete it is much like constructing a hand made wall of solid rock.

Formwork is set up creating the desired shape of the section of wall; damp material is poured in to a depth of between 100 to 250 mm (4 to 10 in). A pneumatically powered backfill tamper — something like a hand-

In modern variations of the method the rammed earth walls are constructed on top of conventional footings or a reinforced concrete base, sometimes with extra ground insulation from a horizontal layer of Styrofoam. Some builders also add colored oxides or other items such as bottles or pieces of timber to add variety to the structure.

Once completely cured the walls are very workable. It is easy to drive a nail or screw into them and they can be patched if necessary with the result being undetectable if the same material was used.

One of the significant benefits of rammed earth constructions is its excellent thermal mass; it heats up slowly during the day and releases its heat during the evening. This can even out daily temperature variations and reduce the need for air conditioning and heating. On the other hand, rammed earth is not a good insulator. Like brick and concrete (which also have excellent thermal mass), rammed earth is often insulated in colder climates. The thickness and density of the walls lends itself naturally to soundproofing and the materials used in the walls make them virtually fireproof.

Rammed earth has been used around the globe for millennia in a wide range of climatic conditions, from wet northern Europe to dry regions in Africa. Rammed earth walls may be placed within the weatherproof fabric of the building. Depending on conditions walls may also have external insulation, soft plaster, timber cladding or a number of locally specific finishes which are applied to masonry buildings.

ABOVE: Rammed earth walls form part of the entrance building for the Eden Project in Cornwall, England.

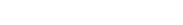

ABOVE: Partially rammed earth wall (with the upper level portion of mud brick) located at Jiayuguan, China, built during the Ming Dynasty (1368–1644).

ABOVE: Rammed earth walls form part of the entrance building for the Eden Project in Cornwall, England. Below: Australian example of Rammed Earth or Pise. Although the technique is centuries old principally the French in the latter half of the 19th century developed this technique. The name pise is a shortening of the word pise de terre. In this method a dryish mixture of sandy soil is rammed into wall forms. Earth buildings in Australia-

.jpg)

ABOVE: Rammed earth walls form part of the entrance building for the Eden Project in Cornwall, England.

Great example of a rammed earth building in Albury, NSW Australia. This building takes full advantage of the environment. Passively designed, this building is equipped with a solar hot water system and gray water collection system.