JARVIS HOUSE UNIVERSAL HOME™ PROTOTYPE

DESIGN AND PURPOSE

JARVIS HOUSE is a hybrid CEB designed home, consisting of a 14-

Ceiling height again became an issue. As with the LMI-

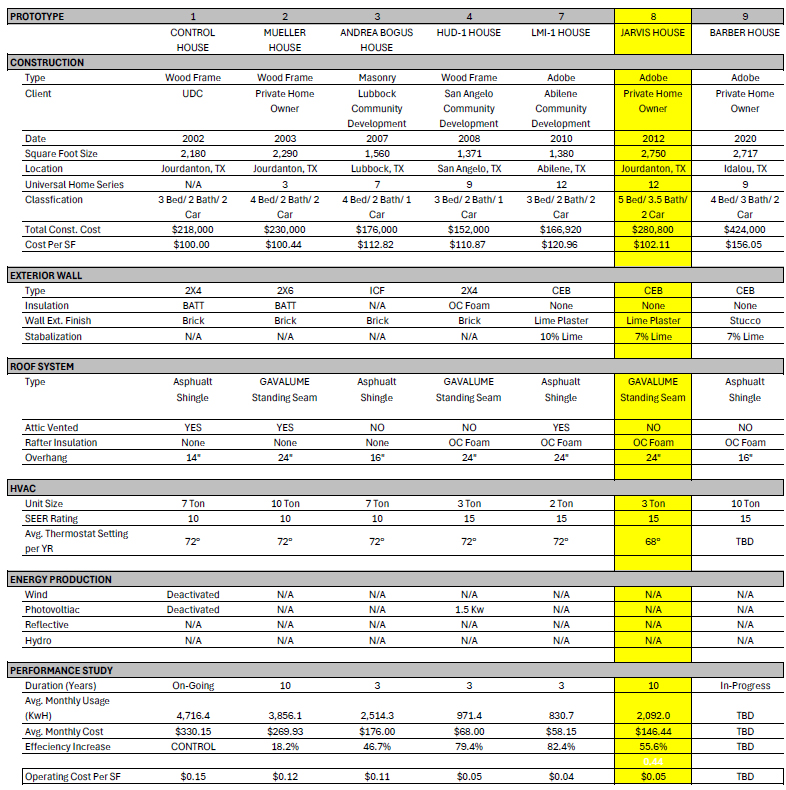

PROTOTYPE COMPARISON CHART

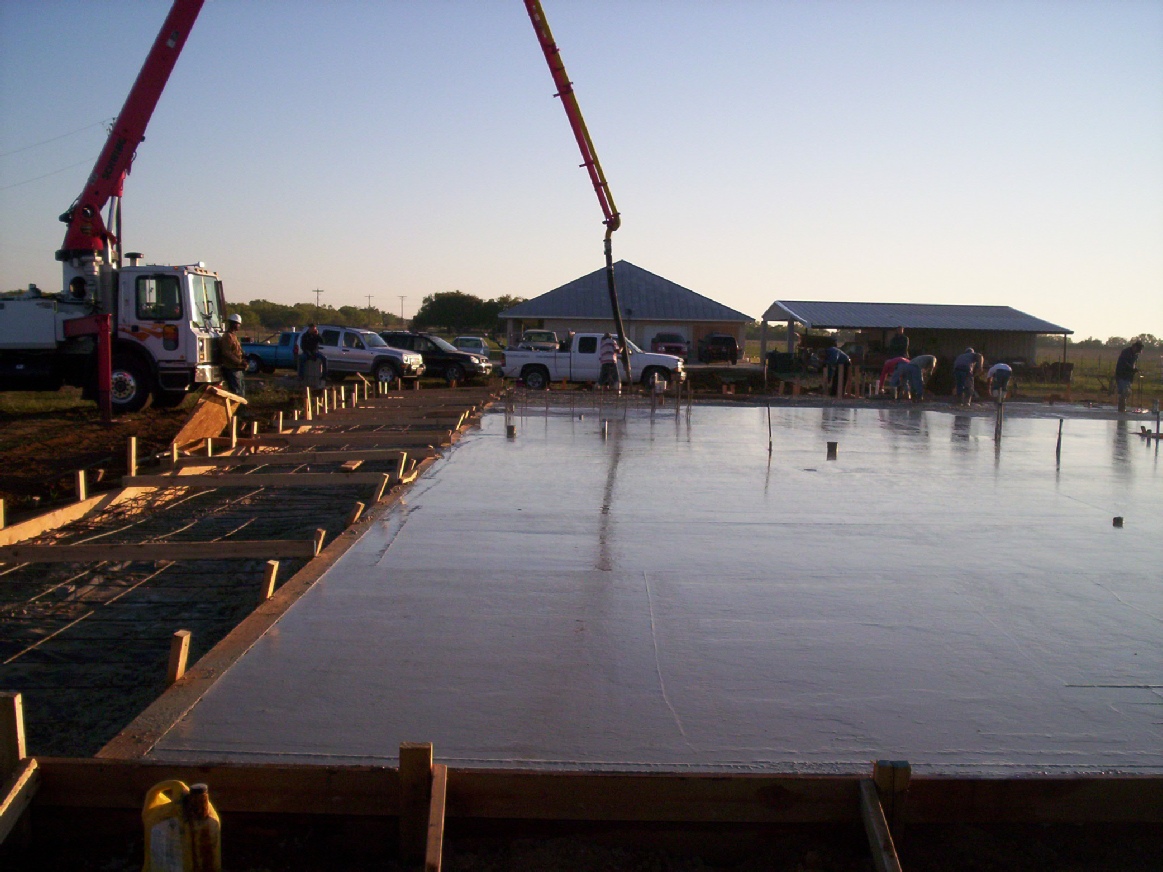

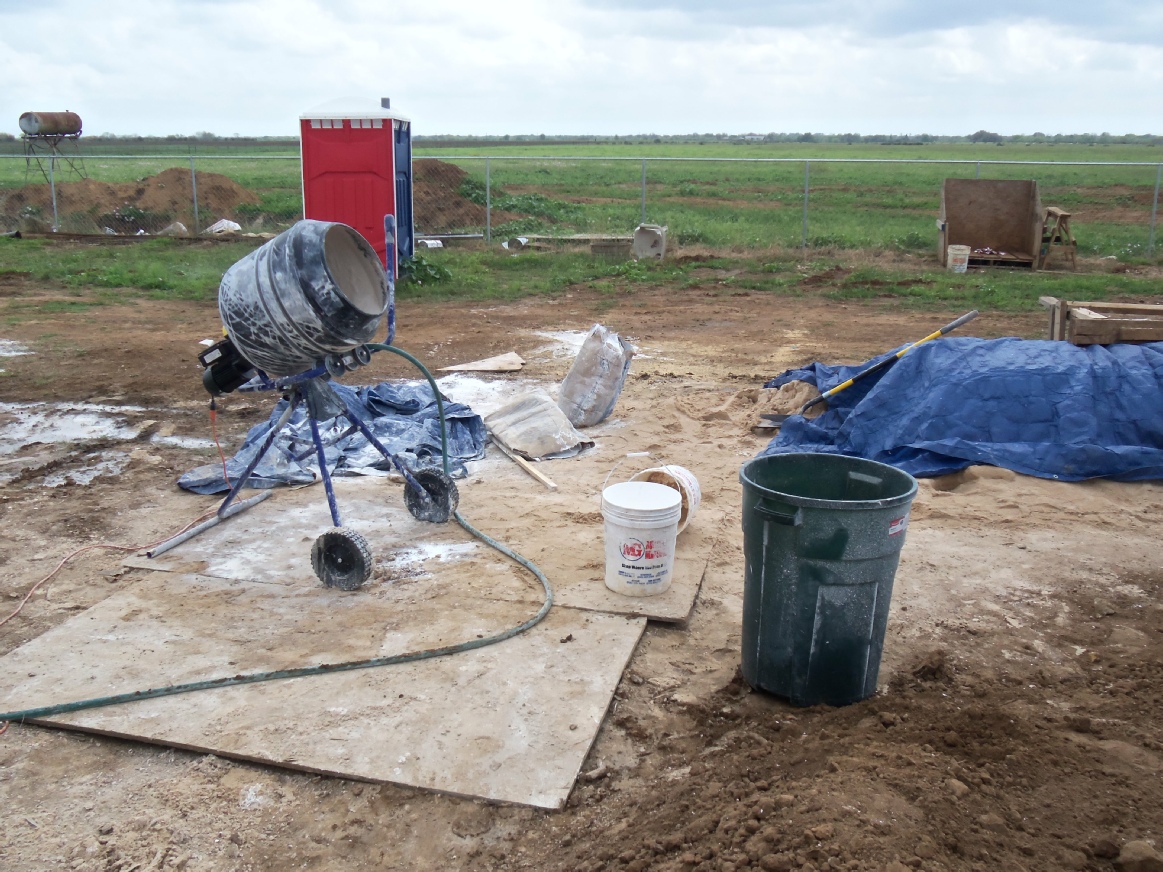

CONSTRUCTION PICTURES

1860 FM 1332 JOURDANTON, TEXAS 78026 | INFO@UDCINC.ORG | 830-

© 2024. SVM Universal Design Consortium LLC ALL RIGHTS RESERVED | Terms & Condoitions

BACK

BACK

TYPE: Residential/ Custom Hybrid Adobe Universal Home™

SERIES: 012 Prototype

YEAR: 2012

CLIENT: Deborah and Mike Jarvis

LOCATION: Jourdanton, Texas

SIZE: 2,750 (5 Bed, 3.5 Bath, 2 Car)

PERFORMANCE STUDY

STUDY DURATION: 10 Years

AVG. ENERGY CONSUMPTION PER MONTH: 2,092.0 Kwh

CONSTRUCTION

WALL ASSEMBLY: Lime Stabilized Compressed Earth Block

ROOF SYSTEM: Standing Seam

TOTAL COST: $280,800

COST PER SQUARE FOOT: $102.11

| Principal |

| BOGUS |

| HUD1 |

| LMI1 |

| JARVIS |

| BARBER |

| STEINLE |

| STEINLE2 |

| TALBOTT |

| SNAP |

| FRACTECH |

| ROLY POLY |

| WATTS |

| WATTS2 |

| VENTURA |

| UD |